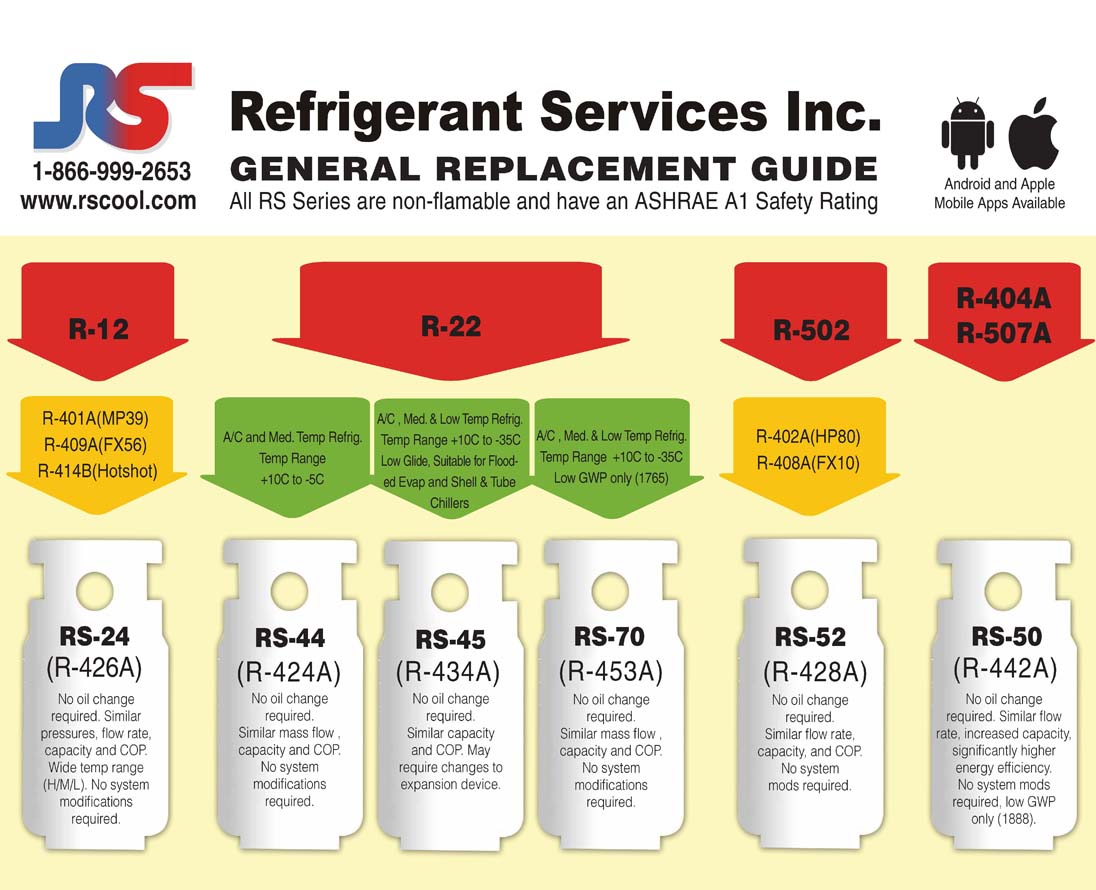

RS-45 (R434A)

Zero ODP replacement for R22 in new and existing systems and compatible with all lubricants

RS-45 with its high cooling capacity compliments RS-44 (R424A), and is compatible with all types of lubricants. RS-45 replaces R22 in both refrigeration & air conditioning applications. With its low glide (one third of R407C), RS-45 can be used in a wide range of applications. RS-45 provides Original Equipment Manufacturers with an alternative to R407C but without the problems associated with a low glide.

RS-45 is compatible both with the traditional mineral and alkylbenzene oils, and also the new polyol ester lubricants. Consquently, R22 can be replaced by RS-45 in both new equipment & in retrofit situations offering considerable cost savings, where the cost of converting to alternatives such as R407C is either prohibitively expensive or technically unsatisfactory (or both).

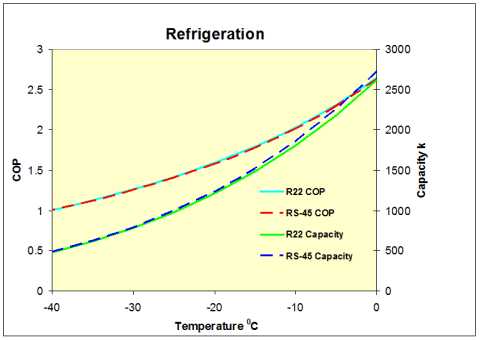

Performance Characteristics

- Suitable in OEM & retrofit applications

- Close match for R22 in cooling capacity

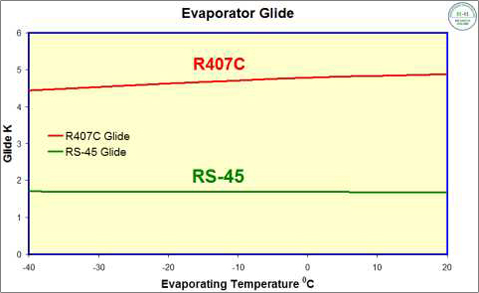

- Low temperature glide

- Near azeotropic property widens application range

- Compatible with MO, AB & POE lubricants

- Effective in low & high temperature applications

- Same compression ratio as R22

- Application in systems with a variable expansion device

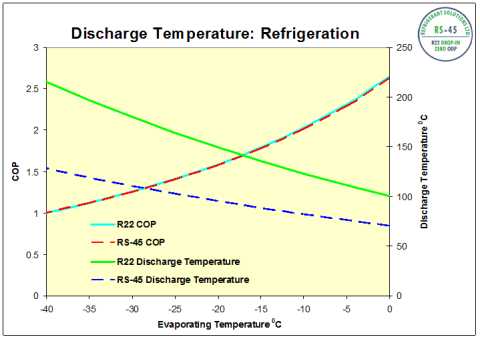

- Considerably lower discharge temperature than R22

- Zero Ozone Depletion Potential

- Non flammable & low toxicity

Conversion Procedure for replacing R-22 with RS-45 (R-434A)

- Ensure the right equipment is available, e.g. Recovery unit and cylinders, container for recovered lubricant, vacuum pump, weighing scales, replacement drier etc.

- Record baseline data to establish the normal operating conditions for the equipment.

- Recover the R-22 charge and weigh recovered amount of R-22 to determine amount of RS- 45 to be charged.

- Replace the filter/drier.

- RS-45 requires approximately 40% greater liquid flow than R-22 so adjustments or modifications to the expansion device and/or liquid line may be required.

- Evacuate the system and liquid charge with RS-45. Begin with approximately 90% of the R-22 charge and add as needed to reach desired evaporator superheat or condenser sub cooling. If the system is fitted with a refrigerant sight-glass and the sight-glass is not indicating a full charge additional RS-45 may be added. Avoid overcharging the system. Depending on the system very small bubbles in the sight-glass may be normal with refrigerant blends.

- Start the system and check baseline data, adjust the expansion device if required. All pressure controls should be adjusted to match the pressure temperature relationship of RS-45 as needed.

- On larger systems with oil sight-glasses, monitor the oil level and add more oil if required to maintain the correct level in the compressor. IF the oil level does not stabilize some of the oil can be removed from the system and replaced with POE oil. Up to 25% of the system oil can be replaced with POE. Starting with an initial 10% and followed by increments of 5% until the oil level stabilizes.

- Check system thoroughly for leaks.

- Clearly label system as charged with RS-45 and type of oil used.

NOTE:

- Systems With Inherent Poor Oil Return, Such As Systems With Unusually Long Suction Lines And/or Low Temperature Systems, May Have Imroved Oil Return Capabilities With Alylbenzene Or Polyolester Oils.

- Flooded Chillers With Evaporator Oil Recovery Systems May Require Poe Oil For Proper Operation. Contact Rsi For More Information And Recommendations.

Applications

Because RS-45 is a close match for R22 with similar cooling capacity, energy efficiency, pressures & low glide, it is suited for use in new equipment by Original Equipment Manufactures where it has significant advantages over R407C. RS-45 does not suffer from the inherent disadvantages of R407C & presents OEMs with a realistic alternative when deciding on a replacement for R22.

Owing to the fact that RS-45 is compatible with mineral & alkylbenzene lubricants, it is suitable for use as a Drop-in replacement for R22 in systems which contain an expansion device. In systems with a capillary tube or fixed orifice, RS-44 (R424A) is the preferred product.

Applications for RS-45 include but are not restricted to air conditioning, refrigerated transport, supermarkets, dairy chillers, cold stores, beer cellars, water chillers and others.

Low Glide Alternative to R407C

RS-45 is a near azeotropic blend with a glide of 1.5°C with compares to R407’s glide of 5°C.

The high glide of R407C can result in icing up of the evaporator & fractionation of the blend which results in high pressures in the condenser & reduced performance. Consequently, the application range of R407C is limited &, for example, is not suitable for use in flooded systems, chillers, low temperature refrigeration, refrigerated transport, cold stores & other applications. RS-45 overcomes these problems with its high cooling capacity, energy efficiency & near azeotropic features as well as being compatible not only with synthetic lubricants such as polyol esters but also mineral & alkylbenzene oils. RS-45 is suitable for use in both air conditioning & refrigeration applications.

Compression Ratio

High compression ratios can result in increased energy expenditure and the potential for compressor damage. RS-45 has a compression ratio which matches R22 across the range of applications where R22 is commonly found.

Lubricants

RS-45 is compatible with both the traditional and new synthetic lubricants so that there is no need to change the oil when converting from R22 to RS-45. RS-45 is suitable for use with mineral, alkylbenzene and polyol ester oils.

Safety

RS-45 is non flammable under all conditions of fractionation as per ASHRAE Standard 34. The components of RS-45 have been subjected to toxicity tests carried out by the Alternative Fluorocarbons Environmental Study (AFEAS), and have been declared to be of low toxicity.

Servicing

Because RS-45 is a blend, it should be charged into the system in the liquid as opposed to vapour form. There is no need to make any hardware changes when converting from R22 to RS-45 but there may be a need to adjust the expansion device.

Physical Properties

| RS-45 | R22 | ||

| Molecular weight | 105.3 | 86.5 | |

| Boiling point (1 atm) | °C | -44.9(1) | -40.8 |

| °F | -48.8(1) | -41.4 | |

| Temperature Glide | °K | 1.5 | 0 |

| Critical temperature | °C | 77.83 | 96.1 |

| °F | 172.1 | 204.8 | |

| Critical pressure | bara | 39.31 | 49.9 |

| psia | 570.2 | 724 | |

| Liquid density (25°C) | kg/m³ | 1096 | 1191 |

| Density of saturated vapour (25°C) | kg/m³ | 53.1 | 44.2 |

| Latent heat of vaporisation at boiling point | kJ/kg | 190(1) | 234 |

| Cv at 25°C and 1 bara | kJ/kg.K | 0.775 | 0.559 |

| Cp (25°C and 1 bara) | kJ/kg.K | 0.861 | 0.662 |

| Cp/Cv at 25°C and 1 bara | 1.111 | 1.185 | |

| Vapour pressure (25°C) | bara | 11.8(1) | 10.4 |

| psia | 163(1) | 151 | |

| Vapour viscosity (25°C & 1 bara) | cP | 0.0128 | 0.0126 |

| Liquid viscosity (25°C) | cP | 0.136 | 0.166 |

| Liquid thermal conductivity (25°C) | W/m.K | 0.0665 | 0.0808 |

| Surface tension (25°C) | N/m | 0.00528 | 0.00808 |

| Specific heat of liquid (25°C) | kJ/kg.K | 1.50 | 1.26 |

| Ozone Depletion Potential | ODP | 0 | 0.055 |

| Flammability limit in air (1 atm) | vol% | none | none |

| Inhalation exposure (8 hr day and 40 hr week) | ppm | 1000 | 1000 |

(1) Bubble point

A Cool New World.

A Cool New World.