RS-50 (R-442A)

TYPE and DESCRIPTION

Other PDF Files

- MSDS (English)

- MSDS (French)

- RSI Brochure

- RSI Data Brochure

- RS-50 Specification Sheet

- Pressure Temperature Chart

- Auchan Meriadeck RS-50 case study

- RS 50 Conversion Auchan Meriadeck case study(French)

- RS-50 (R442A) & Bitzer compressors

- RS-50 Domaine de Moutasse (ENG)

- RS-50 RSI Data Brochure 198

- RS50. New supermarket with RS50

- SK Foods RS-50 (R442A) Case Study

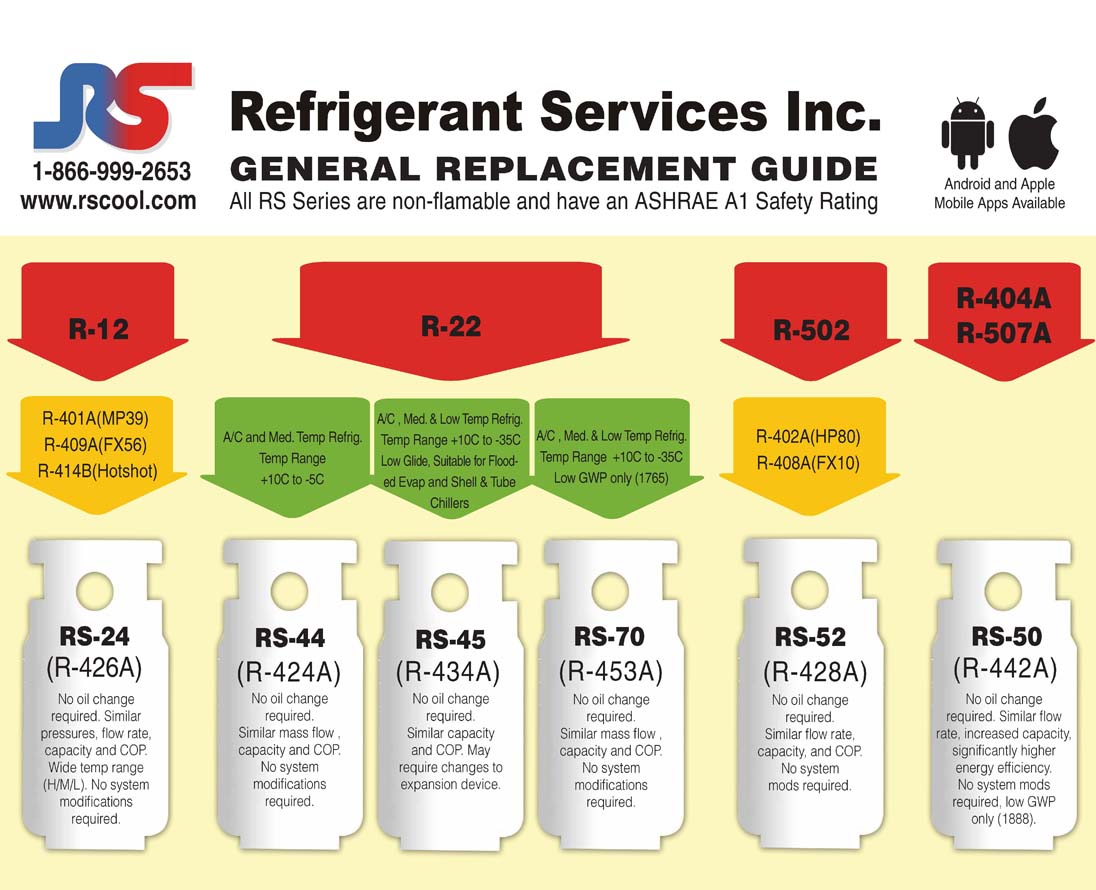

RS-50 is a non-flammable blend of HFC-32, HFC-125, HFC-134a, R-227ea, HFC-152a. It as zero ozone depletion potential. RS-50 is a high efficiency lower GWP replacement for R-404A and R-507A.

APPLICATIONS

RS-50 is suitable for use as a replacement for R- 404Aand R-507Ain existing commercial and industrial low temperature refrigeration systems, walk-in freezers, reach in freezers, etc. It can also be used to replace R-22 in certain low temperature applications.

SERVICE WORK

Because it is a blend, it is recommended that RS- 50 be removed from the container in liquid form only. RS-50 is straight forward to use and requires very little if any retrofitting or system modifications

LUBRICANTS

RS-50 is compatible with polyolester (POE) lubricants. When converting from R-404A or R- 507A. The existing POE oil will not require replacement. Compressor manufacturers’recommendations regarding lubricity should be followed.

COMPOSITION

| HFC -32 | |

| HFC-125 | |

| HFC-134a | |

| HFC-227ea | |

| HFC-152a | |

| Chemical name | Difluoromethane/ |

| Pentafluoroethane/ | |

| 1,1,1,2-Tetrafluoroethane/ | |

| 1,1,1,2,3,3,3,- | |

| heptafluoropropane/ | |

| 1,1-difluoroethane | |

| Type | HFC blend |

| HFC replacement | R-404A, R-507A |

| HCFC Replacement | HCFC-22 Low temp |

| Temperature glide | Approximately 8.3C° |

| Lubricant POE | ODP Zero |

| GWP 100 year ITH | 1888 |

MATERIALS COMPATIBILITY

RS-50 is compatible with all materials commonly used in refrigeration systems previously charged with R-404A or R-507A. It is recommended to check equipment manufacturers retrofit literature and obtain recommendations in regard to materials compatibility.

RS-50 (R-442A) PHYSICAL PROPERTIES

| (R-442A) | RS-404A | R-507A | ||

| Molecular weioht | 81.8 | 97.6 | 98.6 | |

| Boiling point | C° | -46.5(1) | -46.2(1) | -46.7(1) |

| F° | -51 fi(1) | -52 (1) | -52.1 | |

| Temperature Glide | C° | 8.3 | 0.9 | 0 |

| Critical temperature | C° | 82.4 | 72.1 | 70.9 |

| F° | 180.3 | 161.7 | 159.1 | |

| Critical pressure | psia | 690 | 541 | 537 |

| Liquid density at 25 T, | kg/m’ | 1108 | 1044 | 1054 |

| Density of saturated vapour at 25 “C | kq/m | 47,7 | 65.3 | 69.3 |

| Specific heat of liquid at 25 deg C | BTU/kg | n.8220 | 0.8127 | 0.8114 |

| Vapour pressure at 25°C | psia | 192 | 182 | 188 |

| Latent heat of vaporisation at BP | BTU/kg | 252 | 190 | 186 |

| Ozone depletion potential | ODP | 0 | 0 | 0 |

| Global warmina potential | gwp | 1888 | 3922 | 3985 |

| Flammabilitv limit in air M atml | vol% | none | none | none |

| Inhalation exposure (8 hr day & 40 hr w/eek) | ppm | 1000 | 1000 | 1000 |

ENVIRONMENTAL DATA

None of the components of RS-50 contains chlorine so that it has no ability to deplete the ozone layer. RS-50 has a global warming potential (GWP) that is much lower than many of the other HFC blends and because of its very high efficiency the Total Equivalent Warming Impact (TEWI) is very low as compared to other HFC blends.

EVAPORATOR SUPERHEAT

To determine evaporator superheat, measure the suction line temperature and the suction line pressure at the outlet of the evaporator. Using the pressure/temperature chart determine the vapour dew point for the measured suction pressure. Subtract the determined dew point from the actual temperature measured and this difference is the evaporator superheat.

CONDENSER SUB-COOLING

To determine condenser sub-cooling, measure the temperature and the pressure at the outlet pipe of the condenser. Using the pressure/temperature chart determine the liquid bubble point for the measured condenser pressure. Subtract the actual temperature measured from the determined bubble point this difference is the condenser sub-cooling.

RS-50 (R-442A) RETROFIT PROCEDURE

The retrofit procedure for replacing R-404A or R-507A with RS-50 is as follows:

- Ensure the right equipment is available, e.g. Recovery unit and cylinders, container for recovered lubricant, vacuum pump, weighing scales, replacement drier etc.

- If possible before removing the R-404Aor R-507A, operate the system and record baseline data to establish the normal operating conditions for the equipment.

- Recover and weigh the existing refrigerant.

- RS-50 (R-442A) is compatible with POE oil so in most cases when converting from R-404A or R-507A replacing the oil will not be necessary. If the system is charged with MO orAB oil replacing with POE oil is recommended.

- Replace the filter/drier and evacuate the system.

- Charge the system with RS-50 to 90% by weight of the original charge. Note: always remove the RS-50 from the container in liquid form.

- Start the system and adjust the expansion device to obtain the proper superheat and adjust the refrigerant charge if necessary. A liquid line sight-glass if fitted should be used to determine the proper refrigerant charge NOTE: RS-50 has a liquid flow rate approximately 40% lower than R-404A/R-507A so it may be necessary to replace the expansion device with a device that is 40% smaller.

- If the liquid line sight-glass is not indicating a full charge, additional RS-50 can be added to the system. Avoid overcharging the system.

- Check system thoroughly for leaks.

- Clearly label system as charged with RS-50 and type of oil used.

WARNING:

It IS HIGHLY RECOMMENDED THAT THE SUPERHEAT SETTING OF THE THERMOSTATIC EXPANSION VALVE BE CHECKED AND ADJUSTED TO COMPENSATE FOR THE DIFFERENCES IN THE PRESSURE TEMPERATURE RELATIONSHIP OF RS-50 WHEN COMPARED TO THE ORIGINAL REFRIGERANT. AN INCORRECT SUPERHEAT SETTING COULD CAUSE LIQUID REFRIGERANT TO ENTER AND DAMAGE THE COMPRESSOR.

RS Series of refrigerants Pressure/Temperature Charts

RS Series Pressure Temperature Charts indicate both Liquid bubble point and vapour dew point of the RS Series Refrigerant

Liquid Bubble Point: this is the temperature which the liquid refrigerant will begin to vaporize at

the given pressure. Below this temperature the liquid refrigerant will be sub-cooled.

Vapour Dew Point: this is the temperature at which the vapour will begin to condense at the given

pressure. Above this temperature the vapour will be superheated.

A Cool New World.

A Cool New World.